It is known as liquid rubber, a kind of polymer elastic waterproof coating. It sprays at normal temperature with two components, perfectly covers the base and forms a "skin type" waterproof layer. It is suitable for high-speed railway, metro, large public buildings, environmental engineering, housing construction, pipe gallery and other waterproof projects.

After spraying, it can be seamlessly bonded with all kinds of shaped and complex substrates. The bonding performance is excellent: no peeling, no falling off, so as to achieve skin-like waterproof surface.

The liquid rubber coating has ultra-high elasticity and puncture resistance and is therefore especially suitable for expansion joints and deformation joints.

When the waterproof layer is damaged by external force, it can heal and repair by itself, which can effectively solve the damage caused by non-standard construction.

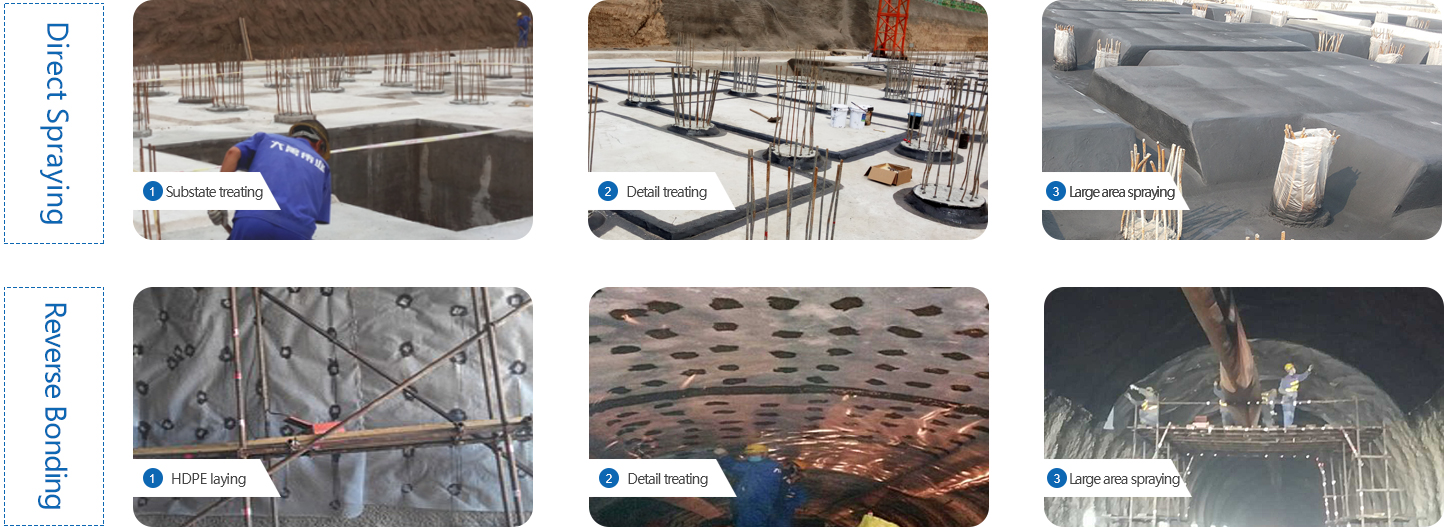

The unique pre-sprayed and reverse bonded properties of Tuling®can completely bond with the concrete poured later, effectively solving the problem of water channeling and leakage in underground projects.

The low temperature flexibility of Tuling® coating can reach - 50 ℃, which is suitable for waterproof engineering in the high-cold area; high temperature resistance can reach 160 ℃; it is suitable for road, bridge, metal roof and other waterproofing projects.

The liquid rubber coating has excellent compactness, which has been tested by Beijing Construction Quality Supervision and inspection station, and the water vapor transmission coefficient reaches 2.85 *10-13. It is suitable for anti-seepage and anti-corrosion engineering such as water conservancy engineering, dam body and sewage treatment.

From production to use, there is no harmful substance emission. Construction at normal temperature and self-extinguishing flame retardant greatly enhance the safety and reliability of construction.

Spraying, brushing, roller coating and other coating methods can be used, which are flexible and simple. Forming the coating in 4 seconds by one step, the daily construction capacity of single equipment is up to 1,200 m2. It can also be applied on a wet base,which improving the construction efficiency greatly.

Tuling®has passed the artificial accelerated aging resistance test of 8,000 hours, and has excellent chemical corrosion resistance, especially suitable for chemical industry, sewage treatment industry and coastal engineering.

The air sound insulation capacity of liquid rubber coating is 24dB, and the noise reduction coefficient is 0.23. It can be widely used in the field of subway and high-speed railway to solve the noise nuisance problem caused by the vibration of rail transit during operation.

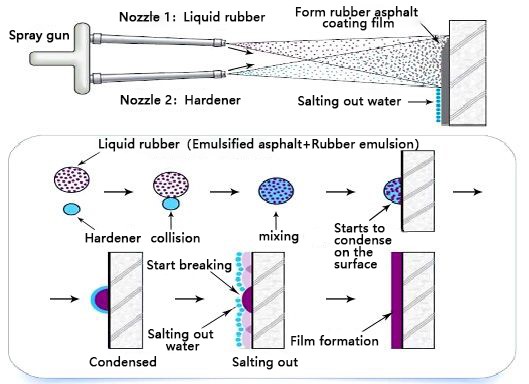

At normal temperature, components A and B are sprayed and atomized through two nozzles in the airless spraying system. After being fully mixed utilizing electrolytes, they reach the base surface instantly and after demulsification, water separation, solidification and condensation form a dense, continuous and complete rubber film, which truly realizes "skin type" waterproof surface.